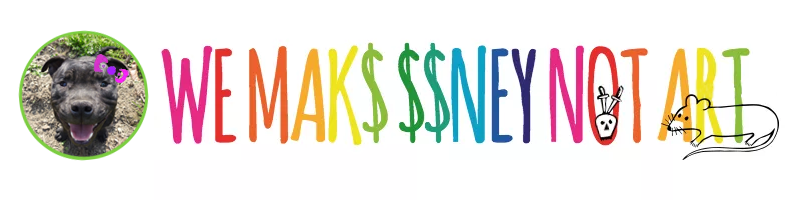

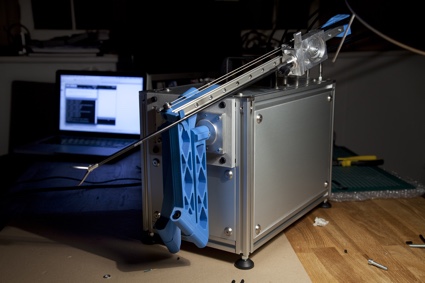

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Robots are transforming surgery. The Da Vinci Surgical System, for example, allows long and complicated procedures to be performed with super human precision and dexterity. All while decreasing patient trauma and providing a more comfortable experience for the surgeon.

Costing up to $2.000.000 however, a surgical robot represents large capital investments and only becomes cost effective after intensive use and thus fits into a more “market driven” concept of healthcare that indirectly contributes to the overall rising medical expenditures.

A surgeon sitting in an ergonomic control console, a few meters removed from the operating table, uses specialized joysticks to control a variety of tiny surgical instruments attached to robotic arms

A surgeon sitting in an ergonomic control console, a few meters removed from the operating table, uses specialized joysticks to control a variety of tiny surgical instruments attached to robotic arms

One of the corollaries of expensive professional healthcare is the rise of communities of uninsured Americans who share videos on Youtube to demonstrate how they performed medical hacks on themselves.

Henry Knoll, How to make your own dental fillings to performing minor amateur surgery, $5 DIY Cosmetic Dentistry, 2009

Designer Frank Kolkman, a new graduate of the Design Interactions course at the Royal College of Art in London, wondered if a compromise could be found. His OpenSurgery project investigates whether building DIY surgical robots, outside the scope of healthcare regulations, could provide an accessible alternative to the costly professional healthcare services worldwide.

There have been several attempts within the robotics community to come up with cheaper and more portable surgical robots. The RAVEN II Surgical robot, for example, was initially developed with funding from the US military to create a portable telesurgery device for battlefield operations. The machine is valued at $200.000 and all of the software used to control the RAVEN II has been made open source. However, The Raven doesn’t have the (often costly) safety and quality control systems in place, required by regulation to allow it to be used on humans meaning that it might take a while before the RAVEN II will be fully embraced by regulatory and commercial worlds. In any case, most medical hacker communities would still be unable to afford its $200.000 price tag.

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

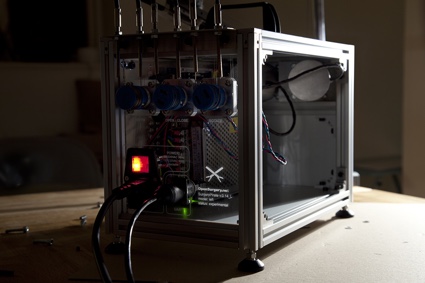

For the past five months, Kolkman has thus been trying to build a DIY surgical robot for around $5000, by using accessible prototyping techniques like laser cutting and 3d printing and by sourcing as many ready-made parts as he could find.

Designing a surgical robot that could perform laparoscopic surgery (a surgery so minimally invasive that it is also called keyhole surgery) presents a number of challenges. The designer found an answer to each of them:

– the many laporoscopic tools that the robot would have to handle can be ordered directly from their Chinese manufacturers using Alibaba.

– these tools are usually sterilized in an autoclave, a machine that uses high pressure and hot steam that is not very likely to be accessible to many people. The bulky machine could be replaced by a domestic oven (for stainless steel instruments) or a microwave (for plastic parts.)

– Kolkman also replaced the trocar, a medical device that functions as a portal for the subsequent placement of other instruments, with a design that uses 3d printed parts controlled by DC servo motors that rotate around a central pivotal point.

Frank Kolkman, OpenSurgery (domestic sterilization), 2015

Frank Kolkman, OpenSurgery (domestic sterilization), 2015

The electronics to control the robots were copied from designs used in 3d printer communities, while the software was build with Processing.

The main challenge the designer encountered however was intellectual property. In a bid to make the project open source, Kolkman tried to develop his own mechanisms. Unfortunately, it appeared that most of the fundamental concepts that allow robotic surgery have already been patented. Fortunately, he also found out that as long as you make parts protected by intellectual property in private and for non commercial purposes they are theoretically exempted from patent infringement.

Frank Kolkman, OpenSurgery, 2015

After five months of iteration, the robot does move. The designer concludes:

And based on my experiences the concept of a DIY surgical robot is surprisingly plausible. If you would be able to build a community of makers who bring the same amount of attention and dedication to building surgical tools as they do to designing 3d printers and cnc machines these days, I believe accessible DIY surgery equipment would be within reach.

And of course you still need a trained surgeon to operate the machine.

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015

Frank Kolkman, OpenSurgery, 2015