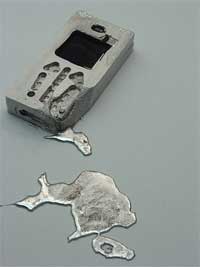

For their Metal Phone project Jack Schultze and Matt Webb (blogo-famous for their Availabot work) have been using a low-melting point alloy to cast and recast a mobile phone shell using only hot air or water.

Metal Phone comes with a machine that melts and reforms a phone around the internals of a standard Nokia handset (the 5140i). The idea is to discuss the local factory angle of personalisation: Could purchasing a mobile phone be more like a performance of manufacture? Could it be more like a vending experience?

Recasting machine and Metal Phone melting

Recasting machine and Metal Phone melting

Using the Metal Phone is not meant to be a piece of cake. The phone is really heavy because it’s mostly lead so you’ll need strong pockets to carry it around. The metal reduces the effectiveness of the aerial so you’ll need to be closer to the transmitter. If you leave your mobile on the dashboard of your car on a hot day, you’ll come back to find the components in a pool of liquid metal. It’s not advisable to hold the phone in your hands for too long because cadmium is present in a low concentration.

The Nokia 5140i is an illusory object. Disconnected from the network when you’re underground, it becomes a lump of plastics and metals. Although safe in your hands, you wouldn’t want to eat the components. It, too, would lose its shape in an oven—in time, it would break apart anyway.

Metal Phone seeks to undermine the current experience of choosing a plastic replica fastened by a security tag to the wall of a handset outlet. The machine represents a vending model for fabrication of the phone in-store, extending the production line to the buyer’s palm. Metal Phone proposes and experience when consumers witness and participate in the fabrication of their products through novel techniques at the point-of-sale and subsequently.

Metal Phone is an extension of work for Chris Heathcote of Nokia, Insight Foresight Group (now NEXT) to develop prototypes exploring personalisation in mobile phones.